About the Company

Plzeňské dílo processes various plastic materials (PP, PE, PS, ABS, PA, PC, SMC, BMC, bakelite, and others). We have a very long tradition in the plastic material processing field. That is why we may offer our customers our rich experiences not only with production, but also with the selection of the best materials for their projects. Our technologies also include nitrogen-based injection moulding. Our production programme includes both technical parts for various industrial fields and consumer market products.

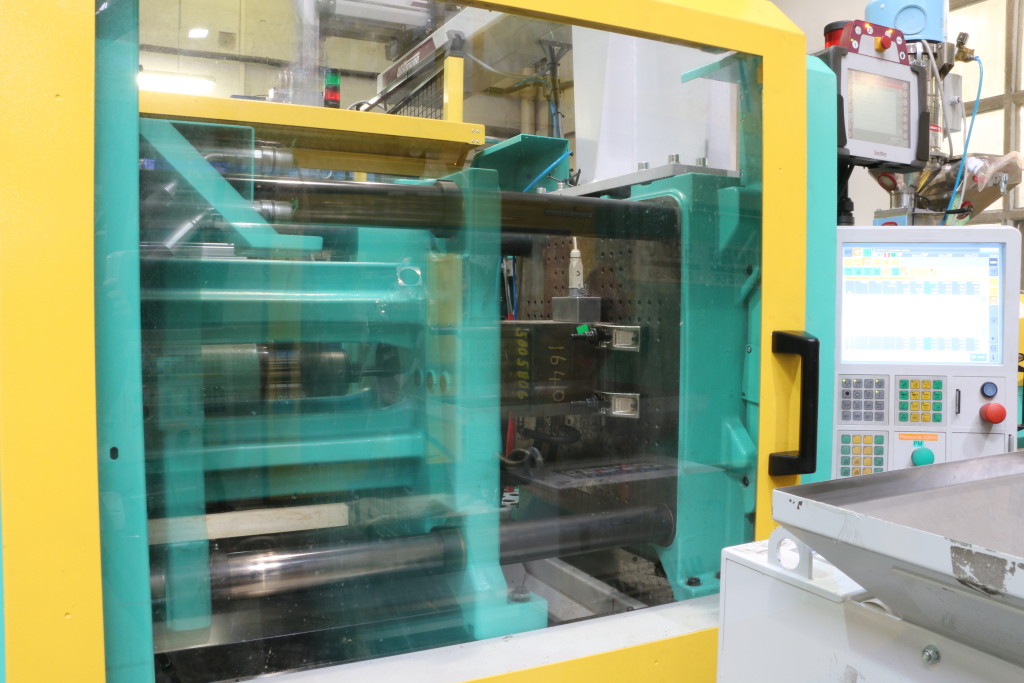

We offer our customers the production of plastic parts through injection or moulding, and we produce moulding tools, which we also maintain, repair, assemble, and install. Our employees operate our 30 injection moulding machines, which produce thermoplastic items, utilizing

the closing force of 25 – 400 tons. Our 25 moulding machines that produce thermoplastic items

apply their closing force of 40 – 600 tons.

We are certificated in accordance with ISO 9001:2008.

History

1943 – Firm foundation (30 July 1943)

1945 – Registration in the Register of Companies (12 December 1945)

1957 – Installation of the first thermoplastic item moulding machines in Pilsen

1958 – Beginning of production from thermosets in Velhartice

1961 – Beginning of glass laminates laminating

1971 – Initiation of thermoplastic material injection at the Skladová Street in Pilsen

1972 – Concentration of the cooperative’s centre at Skladová 8 in Pilsen and initiation of the

development of the plastic production basic facility

1997 – Expansion of the Pilsen facility

2004 – Expansion of the Velhartice facility

2006 – 2011 – Acquisition of new moulding machines with closing force over 350 t

2008 – Acquisition of the 2K technology